The infrastructure improvement will increase berth capacity at Garden City Terminal by 25 percent (1.5 million TEUs,) to 7.5 million TEUs per-year.

(Georgia Ports Authority photo)

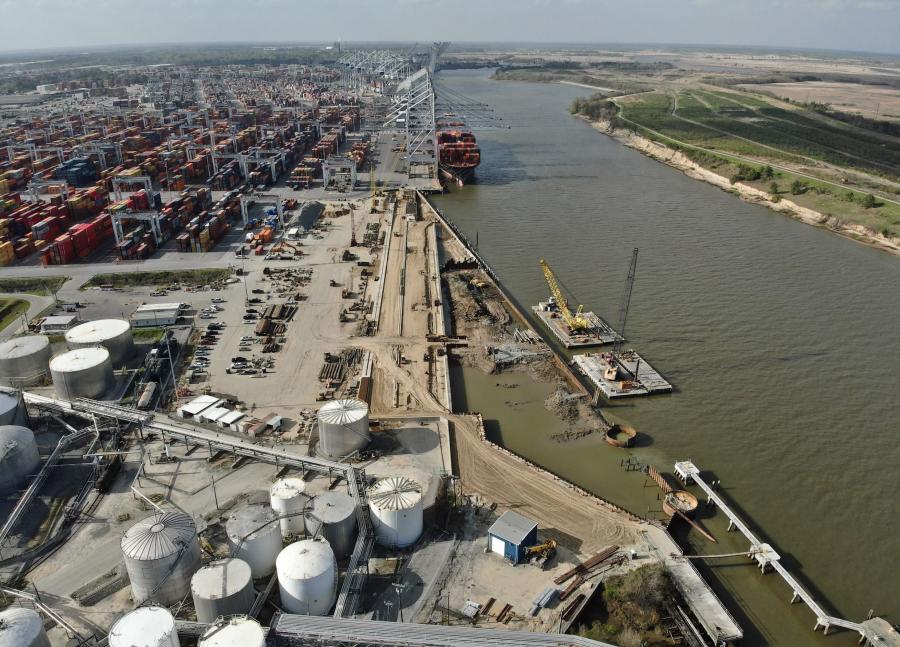

As part of its ongoing expansion of the Port of Savannah, the Georgia Ports Authority (GPA) began renovations of Berth 1 at the Garden City Terminal (GCT) in April 2021, a project that will be completed this July by The Industrial Company (TIC).

The $138 million project, now 75 percent complete, is being financed by GPA's internal capital funds and a federal grant by the Maritime Administration.

"When Berth 1 improvements are finished in July, the port will be able to simultaneously serve seven vessels, including four 16,000-TEU ships," said Chris Novak, GPA's senior director of engineering. "The improved berth will add 1.5 million 20-foot equivalent container units of annual berth capacity. Eight new ship-to-shore cranes are on order, among the largest such machines in North America. Four have arrived and are being commissioned. Another four are on order, two of which will serve Berth 1 and two will work the upriver end of the dock. For customers, the expanded berth and crane fleet will provide faster vessel service and better accommodate the big ships calling on Savannah."

Berth 1 is located at the southern, downriver end of Garden City Terminal. The project realigns the dock face to straighten a bend.

"Renovations to Berth 1 will provide additional dock space for the largest vessels calling the U.S. East Coast," said Novack.

The infrastructure improvement will increase berth capacity at Garden City Terminal by 25 percent (1.5 million TEUs) to 7.5 million TEUs per-year.

The largest ship-to-shore cranes that will operate at Berth 1 are manufactured by Finland-based Konecranes and will reach a height of 165 ft. with a span of 130 ft. between the legs. The first four have been delivered to Berth 1 and are undergoing final commissioning exercises, with initial operations to take place in July. Two additional cranes at the Berth 1 location are expected to be delivered and commissioned this fall.

"These cranes are delivered nearly fully assembled and are placed on newly constructed crane rails that can handle the heavy loading/unloading of shipping containers," said Novack.

The project was designed by Moffatt Nichol out of its Savannah office.

"Several obstacles that required innovative solutions, included coordinating the delivery of the cranes with the newly constructed berth facility," said Novack. "In addition, construction of the Berth 1 improvements while container operations continued adjacent to Berth 1, posed many challenges as well."

Work-wise, TIC has completed the realignment of Berth 1 that allows for the largest cranes to service the biggest vessels .

"A coordinated effort between multiple parties, including Moffatt Nichol, TIC and the GPA, has produced a successful Berth 1 delivery that is on time and within budget," said Novack.

TIC worked six days a week and with multiple shifts that included night time activity to complete the project on time. An operating Berth 2 with vessels and container operations required the construction of the Berth 1 realignment to take place in a very confined and specific area. The coordination between TIC and GPA to allow the port operations to continue while construction took place was a high priority for the project.

TIC and GPA are partners and stakeholders for the delivery of the project. As a single team, issues were resolved quickly and without major delay in order to keep the project on schedule.

The realignment of Berth 1 to handle larger vessels and increase overall capacity was no easy task.

"The entire existing Berth 1 facility was demolished and rebuilt to match the alignment of Berth 2, creating a straight docking facility that can accommodate larger container vessels," said Novack. "Demolition of the Berth 1 took place throughout the project as phases were taken out and worked. The additional capacity at Berth 1 will be complemented by container yard expansions currently under way at GPA's Garden City Terminal West project, which will add 100 acres of container storage."

The work included the dismantling and removal of more than 12 massive dockside cranes, several of which were dismantled simultaneously The cranes contained many steel sections.

The demolition plan was based on taking out sections from one end to the other. Crews removed concrete, which was followed by the old underground utilities and infrastructure. The next step was to prep the site for the new facility — installing new utilities, earth work, and preparing the base for the new concrete surface.

This work was equipment driven, utilizing loaders, excavators, dozers, wheel-loaders, vertical lifts and many cranes (crawler cranes and several placed on barges). Land-based cranes were positioned adjacent to the working sections of the port — container yards and oil storage tanks and they helped to place new pipes and rebar for the concrete pours. Barge-based cranes helped to demolish piles — a minimum of 50 — many of which were in the water.

A good number of barges were employed, some on their own and others linked together to create large work areas.

Coordinating the activities of the cranes and other equipment demanded serious planning for some very complex operations.

The full reconstruction of Berth 1 required hundreds of new concrete piles, which required pours. Many of the piles were rebuilt in open water. This work was assisted by shore and barge-based cranes. CEG

Today's top stories