Among the project’s many challenges, the biggest is to keep the pace of the work steady, despite the situation COVID has created with health and safety rules and control of international deliveries.

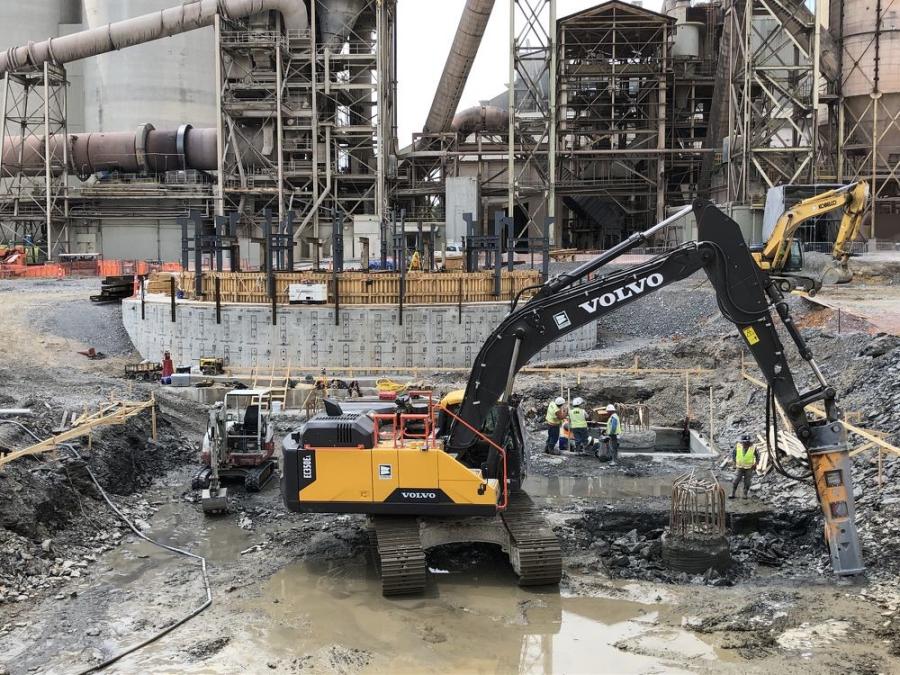

(Hugh Hunter photo)

Described as the largest capital investment in the history of St. Clair County, a more than $250 million expansion of National Cement's plant in Ragland, Ala., is well underway. Officials say a new state-of-the-art kiln will save jobs and allow the plant to remain open for at least another half-century once the two-year project is completed.

"Our present plant was built in the 1960s and modified and modernized in the late 1970s, early 1980s," said Spencer Weitman, president of National Cement Company of Alabama Inc. "By building a new plant, we can incorporate the latest technology and will operate the most efficient plant in the U.S. The new plant will allow National Cement Company of Alabama Inc. (NCC-AL) to continue its operations for another 40 to 50 years into the future."

Weitman said now is a good time to perform the work.

"With our existing plant, NCC-AL had maximized its production and would not be able to grow in the future and meet the needs of our customers. We needed to build the plant to position ourselves for future growth. Also, with the new technology and fuel that will be used, we will reduce our carbon footprint."

With a customer base in Alabama, Mississippi, Tennessee, Georgia and South Carolina, NCC-AL is adding a new high-tech kiln line to its southeastern operation, which includes a new roller mill, preheater, rotary kiln and clinker cooler.

Overall completion of the project is approximately 60 percent, with general and detail engineering almost finished. In addition, civil works are close to wrapping up. Structural steel erection/plate work and equipment erection are the main current activities, with electrical work initiated.

Pre-assembly work began in March 2020, with first clinker production expected in the first trimester of 2022. Seeing the project moving closer to completion is rewarding for everyone involved in the project.

"It is with great pride and a lot of humility that the project team approaches this last year before the commissioning," said National Cement Project Manager Hervé Lapillonne. "NCC-AL's goals for this project are timely commissioning of the plant while staying within the budget, continuing the construction work at the level of performance expected, while continuing to carefully observe all safety rules, and accomplishing it all despite the current COVID environment.

"The project will improve the energy efficiency and increase the clinker production capacity of our manufacturing facilities by supplementing the existing kiln line capacity with the new kiln capacity (additional 5,000 mtpd) and adding an installation to receive and introduce alternative fuels at the calciner," said Lapillonne.

Thyssenkrupp is the supplier for all the equipment, and H&M serves as the main contractor.

"Both of these companies are well-suited to our project because they are well organized, technically knowledgeable and have construction experience with projects of similar scope and size of our project," said Lapillonne. "Additionally, the vision, values and standards to which we hold ourselves are adhered to by each of these companies as well."

Cement operations began in 1908 at the current plant site in Ragland. The company was purchased by the Vicat Group of France in 1974.

"Vicat was founded 170 years ago following in the footsteps of Louis Vicat, who invented artificial cement in 1817," said Weitman. "Operating in 12 countries today, the group offers top-class mineral and bio-based construction materials and service that meet the needs of the construction trades."

According to Lapillonne, of the project's many challenges, the biggest is to keep the pace of the work steady, despite the situation COVID has created with health and safety rules and control of international deliveries.

All activities are progressing at the expected pace, thanks to a joint team effort among the owner, project team and the onsite employees of the plant, supplier and contractor.

The concrete structure was built using vertical slipform construction, which required days of round-the-clock ready mix deliveries to complete.

"Coordination among the slipform contractor, the ongoing work at the construction site and the ongoing operations of the existing plant with concrete supplier Kirkpatrick Concrete was a challenging undertaking, but was handled superbly by all involved with coordinated management," said Weitman.

The slipform work was, in fact, an intense undertaking.

"Once the pouring started, there was no stopping until it was complete. It was a ‘slipform pour.' which means the forms were constantly moving up as concrete was being placed. Total amount of concrete was approximately 5,000 cubic yards with a total placing time of 10 days. The pour was 24 hours per day."

The concrete structure is almost completed, with only a few minor unfinished areas remaining. Two large foundation pours were made, including a mud mat to provide a foundation for a large mat pour.

"The mud mat totaled about 800 cubic yards and was poured in two parts (600 cu. yds./200 cu. yds.)," said Weitman. "The foundation pour totaled about 1,500 cubic yards and was completed in one pour. Three Kirkpatrick plants were utilized in the foundation pour. Two plants could have handled that volume, but a third was added to ensure there would be no problems."

Lapillonne said construction milestones include initial activity at the site, the first structural steel erection and the blending silo civil works completion last December. Tasks yet to be completed include kiln erection in June 2021, refractory works scheduled to begin June 2021 and the accelerated pace of electrical works anticipated for May 2021, following mechanical erection works.

Massive equipment being installed includes a new roller mill, preheater, rotary kiln and clinker cooler, with an additional phase calling for a new clay crusher and storage operation. This called for utilization of two major crawler cranes at the site for the duration of the construction, with additional cranes being added as construction needs dictated. Main materials required on the job include concrete and rebars, structural steel, steel plates and electrical items.

As for the most time-consuming part of the work, said Lapillonne, "That would be the coordination of all personnel involved, timely order and delivery of equipment and supplies and communication among the companies and subcontractors involved in this project. Our success in this regard, all while keeping the Ragland plant operating at its standard level, has been the key to our success with this project to this point."

Weitman noted that the city, county and state were all helpful in bringing the project to reality.

"NCC-AL worked hand-in-hand with each of these entities and their leadership to get our project started. By building the new plant, we have secured a place for our employees to work at good jobs with great pay and benefits well into the future." CEG

Today's top stories