The project was originally divided into four phases, but the project team has worked together to combine phases to advance work and maintain an aggressive schedule.

Started in May 2017, Halley Engineering Contractors Inc. is a year away from completing the Florida Department of Transportation's (FDOT) $33 million NW 87 Avenue Roadway Project between NW 74 Street and NW 103 Street that it is taking place in western Miami-Dade County.

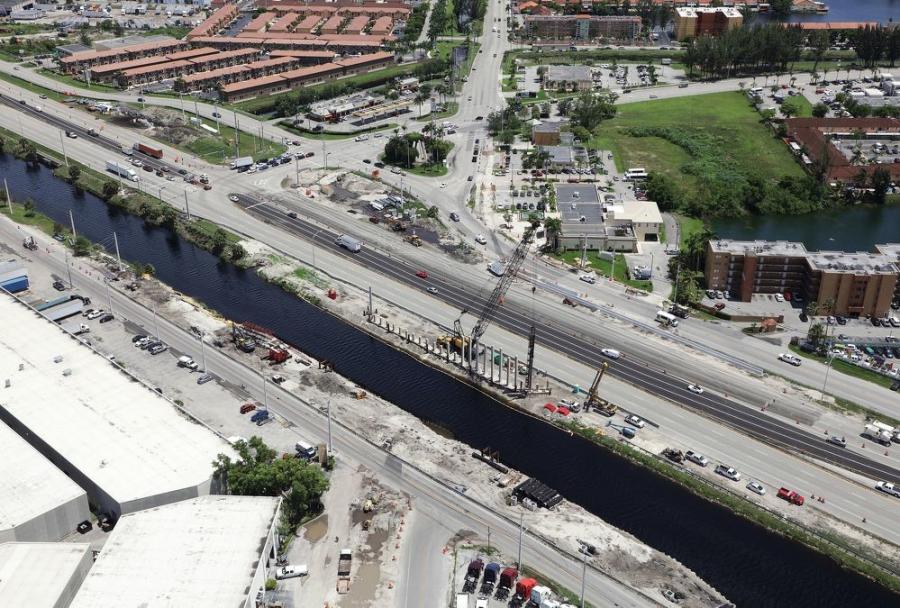

The 2-mi. project will construct a four-lane divided roadway with a painted median; a new bridge over the Miami River Canal that will link the Town of Medley and City of Hialeah Gardens; new sidewalks and pedestrian ramps; five new signalized intersections; new street lighting; new pavement markings and signage; and provide dedicated and shared bicycle lanes, as well as install drainage and water mains.

“This project is providing the long-awaited missing link along NW 87 Avenue that will help alleviate traffic congestion in the area,” said Enrique Tamayo, the project's senior engineer with RK&K. “The new bridge and wider roadway will not only improve traffic flow, but will make the corridor more welcoming for the businesses in this community. Pedestrians and bicyclists will also benefit from new continuous sidewalks and bike lanes.”

The new infrastructure was designed by R.J. Behar & Company Inc.

“This project has required a lot of coordination with not only the local municipalities and agencies, but we are also building a brand-new section of roadway through what was previously undeveloped land,” Tamayo said. “This also requires working closely with FEC as the section of new road will pass across an existing railroad track.”

The contractor has been installing the underground infrastructure and rebuilding the roadway one half at a time in sections throughout the corridor. Nighttime work has been performed for certain drainage activities and weekend intersection closures are implemented to rebuild an area as quickly as possible.

“When we speak with local business owners, they tell us this project has been 20 years in the making,” said Heather M. Leslie, the project's community outreach specialist. “This project is an important enhancement to the community so we are coordinating with them to do whatever possible to reduce the impacts of construction.”

Completed sections of road have been reopened as quickly as possible to minimize disruption. FDOT coordination of the work includes providing clearly signed roadway detours and additional signage to ensure businesses remain visible during the work, coordinating access with businesses in advance when there are anticipated impacts, meetings with stakeholders as needed to answer questions and schedule work, and sending advisories to the community with upcoming lane closure information.

“FDOT is employing various tools to communicate and minimize the traffic impacts,” Tamayo said. “The community has been very understanding and supportive of the work. Everyone is looking forward to the better corridor.”

Halley Engineering's contract includes an incentive for the contractor to complete the work by July 9, 2019.

The project was originally divided into four phases, but the project team has worked together to combine phases to advance work and maintain an aggressive schedule.

“There's adjacent work in the area being performed by other contractors so everyone has had to coordinate activities on a much larger scale,” said Thomas Weeks Jr., Halley's project manager. “It's critical that everyone's schedule stays on track because we rely on one another's progress when scheduling work and mobilizing our crews. There's lots of meetings, phone calls and emails to stay organized.”

To meet this goal, work continues on the new bridge over the Miami River Canal. The new bridge (130 ft. long) will consist of eight total lanes, including turn lanes in both directions. The bridge design also takes into consideration a future widening on Okeechobee Road.

“The bridge has unique features associated with it,” said Tamayo. “It includes a bulkhead steel sheet pile wall along the south side of the canal with deadman anchors. Because the canal right-of-way is owned by the South Florida Water Management District [SFWMD], careful coordination has been ongoing with that agency.”

Peak days have more than 50 Halley and subcontractor employees on site. Among the major subcontractors are: Under Power Corp. for lighting and signalization; Roadway Construction for drainage and watermain; and the Construct Group for concrete work, including bridge work, gravity walls, curb and sidewalks.

“We have a great relationship with our subcontractors and have worked together on numerous projects,” said Weeks.

In terms of materials, 26,487 sq. yds. of asphalt and 47,829 cu. yds. of earth will be removed, with 3,818 cu. yds. of concrete, 22,912 tons of asphalt, 119,804 sq. yds. of earth, and 458,185 lbs. of steel to be brought in.

Halley is using a fair amount of equipment, including: two cranes — a Manitowoc 3900W and a Grove RT875C 75 ton; six excavators — a Komatsu PC300LC, a Kobelco SK210LC, two Cat M318Cs, a Komatsu PC400LC and a Volvo EC150; two dozers — a John Deere 750J LGP and a Cat D5K; three loaders — a Cat 980H, 256C, and a 262C; six rollers — a Hamm HD14VV, a Wacker RD11A, an Ingersoll SD100 TF, a Hamm 2420D, a Volvo SD100D, and a Cat CB-534D XW; and two pavers — both Cat AP1055Ds.

“Some major issues we have with equipment are blown tires, broken hoses and broken teeth on buckets just to name a few,” Weeks said. “The key is that we have mechanics that come in and out of the project daily to service equipment, so we can minimize any damage and to keep our equipment in tip-top shape.”

Halley purchases and rents equipment from dealerships such as Ritchie Bros., Kelly Tractor, Dobbs Equipment, Meco Miami and Flagler Construction Equipment.

Tamayo is pleased with the progress of the work and the team work that is being demonstrated daily.

“The team is aggressively pursuing work throughout the corridor and working together to tackle multiple areas at a time,” he said. “The goal is to beat the incentive date and deliver a quality project that everyone can be proud of and will serve the current and future needs of the community and travelers of the area.”

CEG

Today's top stories