Construction Equipment Guide

470 Maryland Drive

Fort Washington, PA 19034

800-523-2200

☰

×

Equipment and Specs

-

Parts Search

Heavy Equipment Specs

Wanted to Buy

CEG Bargains

All Equipment Categories

Aerial Lifts Aggregate Equipment Agricultural Equipment Air Compressors Asphalt / Concrete / Paving Asphalt Pavers Attachments Backhoe Loaders Cold Planers / Milling Machines Compact Track Loaders Compaction Equipment Conveyors / Feeders / Stackers Cranes Crawler Carriers Crawler Dozers Crawler Loaders Crushers Drills Dumpers Excavators Forestry Equipment Forklifts Landscaping Equipment Light Towers Material Handlers Mini Excavators Miscellaneous Equipment Motor Graders Off-Highway Trucks Off-Highway Water Trucks On-Road Trucks Pipelayers Power Systems and Generation Pumps Scrapers Screening Skid Steer Loaders Skip Loaders Snow Equipment Straw Blowers / Hydroseeders Sweepers Telehandlers Trailers Trenching / Boring / Cable Plows Utility Vehicles Welders Wheel Dozers Wheel Loaders

Industry News

Company

Subscribe

Equipment

Parts Search

Heavy Equipment Specs

Wanted to Buy

CEG Bargains

All Equipment List

Aerial Lifts

Aggregate Equipment

Agricultural Equipment

Air Compressors

Asphalt / Concrete / Paving

Asphalt Pavers

Attachments

Backhoe Loaders

Cold Planers / Milling Machines

Compact Track Loaders

Compaction Equipment

Conveyors / Feeders / Stackers

Cranes

Crawler Carriers

Crawler Dozers

Crawler Loaders

Crushers

Drills

Dumpers

Excavators

Forestry Equipment

Forklifts

Landscaping Equipment

Light Towers

Material Handlers

Mini Excavators

Miscellaneous Equipment

Motor Graders

Off-Highway Trucks

Off-Highway Water Trucks

On-Road Trucks

Pipelayers

Power Systems and Generation

Pumps

Scrapers

Screening

Skid Steer Loaders

Skip Loaders

Snow Equipment

Straw Blowers / Hydroseeders

Sweepers

Telehandlers

Trailers

Trenching / Boring / Cable Plows

Utility Vehicles

Welders

Wheel Dozers

Wheel Loaders

New Ranger DXR drill rigs can reach places that are off-limits to operators and where other drills fail to operate. They essentially offer the characteristic of conventional Ranger DX series drill rigs, reliability and large drilling coverage area from the standard 189 sq. ft. (17.6 sq m) to an optional 248 sq. ft. (26.4 sq m), in a lighter and more mobile package — a superior solution for hazardous conditions where safe and productive drilling requires advanced radio remote control capabilities.

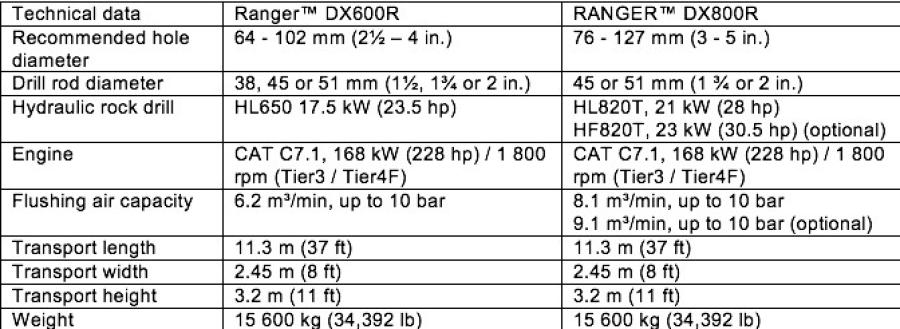

New Ranger DXR drill rigs can reach places that are off-limits to operators and where other drills fail to operate. They essentially offer the characteristic of conventional Ranger DX series drill rigs, reliability and large drilling coverage area from the standard 189 sq. ft. (17.6 sq m) to an optional 248 sq. ft. (26.4 sq m), in a lighter and more mobile package — a superior solution for hazardous conditions where safe and productive drilling requires advanced radio remote control capabilities. The revolving superstructure offers unbeatable drilling coverage and superior stability, due to the counterweight solution, and provides a solid foundation for drilling even on extreme terrain, according to the manufacturer. In terms of productivity, the revolving superstructure turns Ranger DXR truly to a powerhouse enabling up to 60 percent more holes to be drilled per set-up compared to conventional top hammer drill rigs. Together with powerfull rock drills and Rock Pilot+ drilling control systemthe Ranger DXR series represent the highest productivity in non-cabin drill rigs.

The revolving superstructure offers unbeatable drilling coverage and superior stability, due to the counterweight solution, and provides a solid foundation for drilling even on extreme terrain, according to the manufacturer. In terms of productivity, the revolving superstructure turns Ranger DXR truly to a powerhouse enabling up to 60 percent more holes to be drilled per set-up compared to conventional top hammer drill rigs. Together with powerfull rock drills and Rock Pilot+ drilling control systemthe Ranger DXR series represent the highest productivity in non-cabin drill rigs.