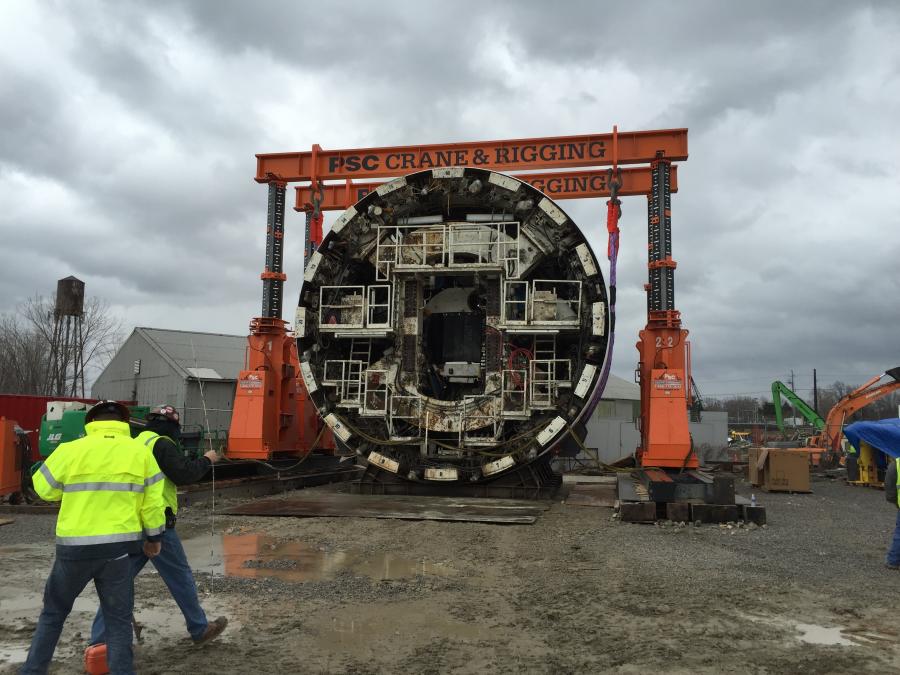

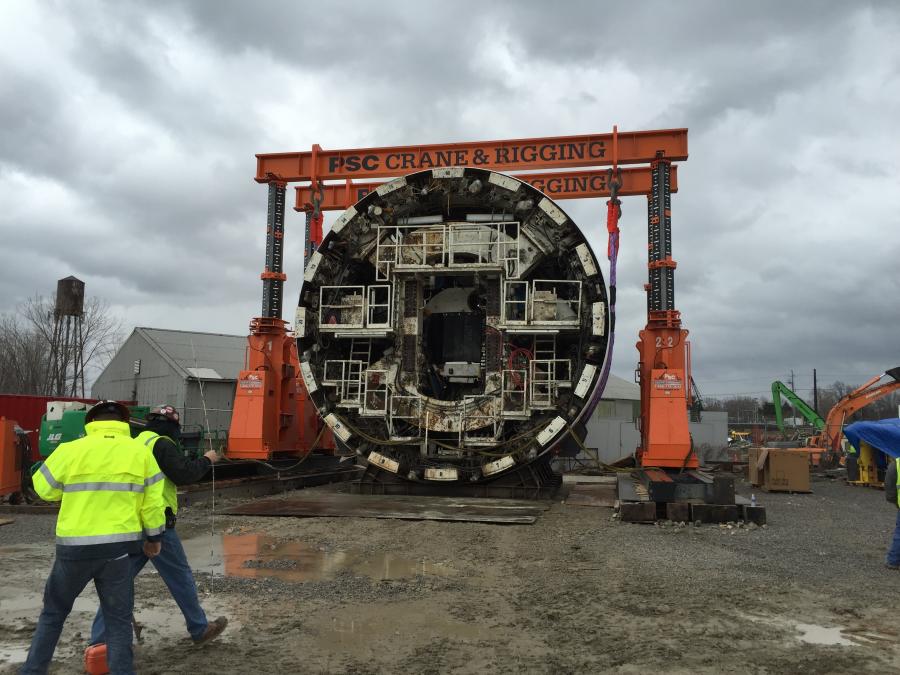

The TBM’s cutterhead in place in the mining shaft.

(Northeast Ohio Regional Sewer District photo)

One of the key elements of the Northeast Ohio Regional Sewer District's (NEORSD) Project Clean Lake is the $153 million, 14,000-foot-long (2.8 mi.) Dugway Storage Tunnel, which is being constructed by the Salini Impregilo/Lane Construction JV (Salini Impregilo S.p.A. and The Lane Construction Corporation).

Construction on the design-bid-build DST, a 24-ft. diameter tunnel located in Cleveland's east side (the Glenville neighborhood) began in 2015 and should be completed by December 2019. The contract was awarded to the JV in November 2014. The DST stretches from the Easterly Tunnel Dewatering Pump Station (ETDPS) to its upstream terminus at Superior Avenue, and it will share the terminus with the Euclid Creek Tunnel (ECT) and connect to the ETDPS.

Equipment was brought deep underground. (Northeast Ohio Regional Sewer District photo)

Once operational, the structure is expected to capture approximately 370 million gallons of combined sewage annually, preventing pollution from entering Dugway Brook and eventually Lake Erie. The DST will store and convey combined sewer overflow (CSO) from ancillary collection and relief sewers, and rather than replace the existing pipes, it will handle any additional flow created by a storm or heavy rains. The DST will be able to store up to 58 million gallons of water and sewage and hold it until the rains subside and the Easterly Wastewater Treatment Plant has the capacity to treat the liquids.

"Flows captured in DST will be pumped to the Easterly plant via the ETDPS, a huge underground pump station designed to pump up to 160MD from the Euclid Creek Tunnel, DST, Doan Valley Storage Tunnel and Shoreline Storage Tunnel, which is still under design," said Jennifer Elting, the NEORSD's senior public information specialist. "DST is a single-pass tunnel, and we used the same tunnel boring machine that was used for the ECT."

Launched in 2011, Project Clean Lake is a $3 billion, 25-year plan to reduce CSO volumes affecting Lake Erie via the construction of seven storage tunnels, green infrastructure and three treatment plant improvements that will reduce CSO by four billion gallons annually.

"When Cleveland entered into its consent decree in 2011, [the city] discharged an estimated 4.5 billion gallons of raw sewage into the lake," noted Salini Impregilo. "Although the volume is half of what it was in the 1970s, the city needs to reduce it even more to meet standards set under the Clean Water Act."

Muck being taken to the surface from the underground cleaning operations for the temporary dam at the ECT-1 (Euclid Creek Tunnel). (Northeast Ohio Regional Sewer District photo)

"The Dugway series of sewer projects is extensive and critical to the future of clean water in the region" Elting said. "It is a network of sewers and tunnels being constructed to reduce combined CSOs, ensuring a cleaner environment for the Glenville neighborhood and beyond."

The Dugway work will create 32,000 ft. of new sewers ranging from three to 24 ft. in diameter. Dugway West was completed in August 2017 ($52 million) and Dugway South was substantially completed in August 2018 ($26 million). The Dugway East Interceptor Relief Sewer project ($11 million, completed in December 2011) also helps to mitigate combined sewer overflows on Cleveland's east side, but this project was completed prior to Project Clean Lake.

The Dugway tunnels, along with the Euclid Creek Tunnel projects (completed in 2015), will handle 950 million gallons annually. And the new tunnels are needed.

"Cleveland's earliest sewers are combined sewers," stated a document distributed to local residents during public consultations. "Built around the turn of the 19th century, these sewers carry sewage and stormwater in a single pipe. During heavy rains, when there is a dramatic increase of water flowing through the sewers, some of the combined wastewater and stormwater is allowed to overflow into area waterways to prevent urban flooding. This combined CSO harms our environment."

Design work for the DST was completed by a joint venture of MWH Americas Inc. and Mott MacDonald LLC.

A design-bid-build contract was selected based on a combination of the NEORSD's governing rules and the many geotechnical, property acquisition, flow monitoring, property and hydraulic work associated with the project.

"Meeting our consent decree dates, CSO requirements, and avoiding the large claims by identifying and investigating all of the major risk items were among the top challenges," said the NEORSD's Doug Lopata. "Via the Euclid Creek Tunnel project, we learned the importance of identifying utilities early on for either relocation or avoidance when possible."

The lifespan of the tunnel is approximately 100 years. The initial boring had the DST at 27 ft. in diameter, but once the precast segmental concrete rings lined the walls, the internal diameter is close to 24 ft. The tunnel is between 200 to 230 ft. below ground and has six shafts of varying diameters and depths, along with a series of concrete structures for the collection and transporting of wastewater and rainwater.

Thus far, the Salini Impregilo/Lane Construction JV has completed the tunnel, six shafts — DST-1, DST-2, DST-4, DST-5. DST-7, and DST-8 — and four adits at DST-2, DST-4, DST-5, and DST-7. The remaining work includes lining the 200 ft. of the ECT tail tunnel, which covers the area from the DST-1 shaft to the ECT tail tunnel. Crews are currently prepping the work site.

"The lining will be cast-in-place and should be completed in October," explained Buck Depew, the NEORSD's construction supervisor for the DST. "We also still have some mechanical and electrical processes to do at various gate structures in order to lift and close the gates based upon the level of CSO in the tunnel. There also remains some flow activation activities, i.e. removing bulkheads at various pick up points."

Depew noted that the project had few challenges.

"We've always had good communications with the JV," he said. "We meet on a monthly basis with progress meeting and we have a dispute resolution board that meets every quarter to bring up any issues — there really weren't any issues that couldn't be resolved just by talking."

While the work occurred in a residential area, all of the sites were fenced off and there were no road closures.

"Some of the sites were tight, but it never became an issue where we had to increase the footprint of our staging areas," Depew stated. "At each site we had separate entrance and exit gates, so there was no backing up into the streets, and if there was any heavy traffic, someone would go out and flag traffic to let people know that we had a big truck coming in or out."

The main mining site for the DST was the same for the ECT project.

The TBM, assembled on the surface, was lowered down the shaft in sections via a gantry system with strand jacks. PSC Crane & Rigging handled the assembly and lowering operation. (Northeast Ohio Regional Sewer District photo)

"We had already established sound walls on the northern side of the property so that the residents whose backyards backed onto it had some protection from the noise," Elting said. "Moreover, the road is a highway exit road, being close to a major highway, and there wasn't a lot of truck traffic up and down the residential streets."

Nor were there any utility issues. The TBM cut through Chagrin shale, which had beds of siltstone.

"All the beds are horizontally laid, and it becomes difficult with the vertical boring machine (VBM) when you get to that layer of siltstone — it is time consuming," Depew said. "But when you're horizontally boring through it, you can undercut it and it will break easily. With the VBM, you know when you get into that hard stuff."

To mine the tunnel, the JV purchased a Herrenknecht 27-ft. diameter, single shield tunnel boring machine from McNally Kiewit JV, which had completed the ECT. The TBM was put into storage in fall 2013 and reassembled at the new site by November 2017. Some minor modifications were made, including an additional grease pump which greased the gaps between the brush seals that stopped grout from getting into it.

A grout pump also was added, as were guide rods to the radial joints to improve the efficiency and installation of the rings.

"We are comfortable with the guide rods because we used them on our last two projects, one in Washington, D.C. and one in Portland," said Jim Kabat, project manager for the JV. "It does require you to be a little more careful as you are installing the keystone piece because the guide rods extend away from the joint surface, but it does help to hold the shape of the ring."

BASF supplied the grout and technical support for the DST operation.

"It took six months of testing to confirm gel times, set times, flowability characteristics — all of the things that you need to get right to do the job successfully," Kabat said. "Most important was to ensure we had flowability to fill the void completely as the TBM moved forward, but also to get the initial set correctly."

Methane gas in the shale posed a threat and it was found in all of the shafts, with work on one suspended for a month in order to vent it. When concentration of methane exceeded 20 percent of the explosion limit, mining operations had to be shut down. A ventilation system was installed to support the tunnel boring operation.

"The system ensured that the gas was always blown out," said Depew.

Assembly of the Dugway Storage Tunnel project's gantry crane. (Northeast Ohio Regional Sewer District photo)

The TBM, assembled on the surface, was lowered down the shaft in sections via a gantry system with strand jacks. PSC Crane & Rigging handled the assembly and lowering operation. The 468-ton main body of the TBM was lowered in piece, as was the 178-ton cutter head.

The DST-1 shaft was used for the launching of the TBM and for the support of the tunneling operations. The shaft was excavated through 90 ft. of soft ground and 112 ft. of shale. The DST-8 shaft was used for the retrieval of the TBM. This shaft was excavated through 22 ft. of soft ground and 127 ft. of shale.

Mining operations, at three shifts per-day, began in April 2017 and were completed on March 21, 2018. To bring the muck to the surface, a continuous vertical and horizontal conveyer system provided by H+E Logistik was installed.

"There were no significant challenges with boring operations and work proceeded as planned," Kabat said. "The average tunnel progress for the TBM tunneling was 71.5 ft. per-day."

Precast concrete segment rings were installed in the tail shield of the TBM for every 5 ft. of the tunnel and they formed the final lining of the tunnel. A Liebherr HS-895-HD 200-ton crane was used to lower the precast concrete segments into launch shaft and they were transported by rail to the TBM segment handling system at the back of the machine. The segments were reinforced with steel fibers.

"The precast segment installation operation went as planned and there were no significant challenges to this work," Kabat staed. "A two-component grout was pumped into the annular space between the outside of the segment and the rock as the TBM moved forward."

The muck was stockpiled on the surface and trucked to an approved location where it could be stored until re-used as fill. A VMT guidance system was used to control the line and grade of the tunnel. The tunnel alignment was programmed into the guidance system and the system ensured that the TBM maintained the proper alignment.

In addition to the launch and retrieval shafts, four other shafts along the alignment of the tunnel were constructed. These shafts varied in diameter from 16 to 32 ft. and from a depth of 200 to 220 ft. The overburden sections of three of these intermediate shafts were supported with steel liner plates and ribs and were excavated by Triad Construction and Engineering.

The TBM before mining, being brought to the mining tunnel shaft. (Northeast Ohio Regional Sewer District photo)

DST-4's construction demanded a deep secant piled wall to give temporary support, which was provided by Nicholson Construction Company. The secant shaft, along with continuous flight auger piles and cased secant pile walls, were key for support of the ground for the DST-4 and DSY-5 gate structures. These structures were built adjacent to the DST-4 and DST-5 drop shafts. According to Russell Cooper, Nicholson's Special Project Division, the DST-4 drop shaft was one of the deepest secant pile structures in Cleveland.

Marra Services excavated the DST-8 shaft using liner plates and ribs to support the ground through the overburden. They excavated the shale with excavators and hydraulic breakers. The shale was supported with rock bolts, mesh and shotcrete. The excavation started in May 2015 and was completed in December 2016. The construction of the liner started in December 2016 and was complete in May 2018

"The work on the shaft went as planned with very few problems," Kabat explained. "Dewatering was required in two locations to depressurize the water level during the excavation of the overburden. In one of these locations the ground conditions did not allow the successful depressurization of groundwater. In the DST-1 shaft, ground freezing was used in place of the dewatering to allow the successful excavation through a portion of the overburden. The ground freezing worked very effectively. The steel ribs were modified to resist the increase in pressure from the ground expansion due to freeze and strain gauges, and load cells were installed on the ribs and behind the liner plates to monitor the load and ensure that it did not overstress the ribs and liner plates.

"A strengthened concrete collar was place in this section of the overburden excavation to ensure that the shaft remained stable during the remaining excavation and the construction of the tunnel," he added. "After completing the excavation of the DST-1 overburden, the shale was excavated using drill and blast methods. This method continued for the excavation of the top heading and bench of the starter and tail tunnel."

Several monitoring points were set up to measure noise and vibration levels from the blasting and mining operations at DST-1 and other sites.

"We never exceed the allowable limits," Depew said. "When we did the shafts, we put blasting mats down and covered them up. If you didn't know that blasting was going on, you would not be able to detect it. We kept the public informed about these operations."

The final element of the project was the connection of the DST to the ECT, which required the excavation of a 45-ft. thick rock plug. The excavation of the rock plug has just been completed and the lining of the connection is underway.

Installing rock bolts. (Northeast Ohio Regional Sewer District photo)

"Under the original contract, the flow into the ECT was going to be stopped so that raw sewage would not be encountered," Depew stated. "Several months ago, prior to excavating the plug, it was determined that we could not take this one leg off-line. It was ungated, so we couldn't even bulkhead it."

This posed a challenge to the designer, NEORSD, and the JV. The solution was to install an underground dam (220 ft. deep) at the bottom of the ECT, which is still in place, to protect the workers that removed the plug and are lining the ECT tail tunnel.

"This was a really good example of everyone working together to collectively come up with the best solution," Elting said. It took a week to construct the dam.

"We lowered everything in and welded it in place," Depew said. "It was not an easy operation. There was a pump near the dam site and when we scanned the face at the bottom, we realized there was approximately 150 cu. yds. of grit and muck that had to be cleaned up. The pump was doing its job with the sediment falling onto the suspension. It took about a week to clean up and we had to clam it out — we couldn't stick in a trash pump and pump it out because it was too heavy."

On peak days there were 125 JV and subcontractor workers on site. Subcontractors were hired locally and regionally. Tallies for the materials removed are still being finalized, as are the amounts of concrete, steel, linear ft. of pipe and other materials that will be brought in. To maintain the TBM, the JV had several on site mechanics.

Kabat's management team includes Roberto Bono, project engineer; Willie Flores, general superintendent; Saeed Tabrizi, construction manager; Derrick Bryson, equipment superintendent and master mechanic; and Scott Lewis, safety manager. CEG

Today's top stories