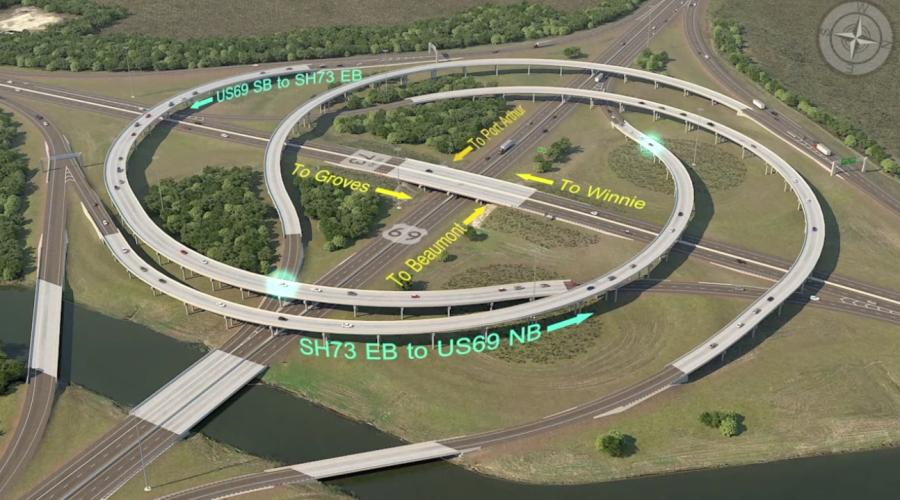

Williams Brothers Construction will completely redesign the U.S. 69 and SH 73 interchange southeast of Beaumont near Port Arthur. Key aspects of this work consist of placing of embankment and the installation of columns.

(Photo courtesy of TxDOT.)

Changing the complete design of an interchange is no small task, but that is what crews from Williams Brothers Construction are achieving near Port Arthur in Jefferson County, Tex.

Maintaining road safety standards and improving traffic flow are the key reasons for the Texas Department of Transportation's (TxDOT) $70 million project to upgrade and improve the U.S. 69 and SH 73 interchange southeast of Beaumont.

For the reconfiguration of the interchange, crews changed the original cloverleaf configuration to a turbine (spiral) configuration.

Work began in November 2021 and is scheduled for completion in late 2025.

New Design

The upgraded interchanged was design by Poznecki-Camarillo LLC with the help of RDV Systems and LJA Engineering.

To date, Williams Brothers has completed the following: mobilization, temporary widening and initial closure and started work on foundation soil improvements. The next 12 months will see crews focus on completing foundation soil improvements, earthwork, bridge foundations and substructure.

"The plan of attack is to open up the center of the interchange to allow for temporary detours and permanent soil foundation improvements while maintaining traffic flow," said Rick Kronenberger, project manager of LJA Engineering. "Poor soils are a challenge. The existing soil conditions called for a well designed soil improvement plan. This plan includes improving drainage for the turbine, installation of soil monitoring cells and wick drains.

"The key aspects of this work is the placing of embankment and the installation of columns," Kronenberger added. "The entire project is demolition and reconstruction."

For the addition of direct connectors, putting in mainlane improvements and improving frontage road and ramps, "the challenges included tying in the direct connects to optimize flow and maintain safety," said Bryce Broussard, TxDOT assistant area engineer (Hardin, Jefferson and Orange counties), Beaumont District.

To construct the new lanes, Williams Brothers is removing of the existing pavement, earthwork moving to prepare to final grade (cuts & fills), subgrade improvement using lime, base placement and concrete pavement surface.

Work to construct the retaining walls and culverts has not started.

Widening and repairing existing bridges and constructing new ones will begin in the near future. One bridge is being widened, two are being replaced and four new ones are being built. The length of the bridges is between 164 ft. to 1,935 ft.

"The time required to complete a bridge varies based on complexity, length and traffic phasing," said Kronenberger. "The time to demolish a bridge depends on traffic phasing and environmental constraints."

The materials from the demolition operations will not be recycled on-site. In terms of prefabricated parts and elements being used, Williams Brothers is bringing in retaining wall panels, bridge beams and bridge deck panels.

The amounts of materials — concrete, steel, asphalt and earth and rock — from demolition and excavation operations and new materials being brought in — are still being finalized.

Williams Brothers crews are using cranes, excavators, dozers, loaders and other standard equipment from various manufacturers. The company purchases and rents equipment from a variety of dealerships in Texas.

Project Need

"This project is going to improve the safety of that intersection and it will bring it up to current highway and safety standards," said Sarah Dupre, a TxDOT public information officer of the Beaumont District.

"Right-of-way constraints while trying to optimize traffic flow is a challenge," said Broussard. "This is a heavy industrialized area consisting of large trucks and large amounts of traffic during peak hours and shift changes. It has a poor soil conditions and high water table. The general contractor is using embankment soil monitoring cells that give a 24/7 look at the settlement of the placed embankment. The turbine design maximizes the use of the existing ROW to provide improved flow for the traveling public who use this interchange daily."

The construction is essentially taking place within the existing right-of-way and should not result in any traffic displacements. TxDOT recently closed two of the interchange's northern quadrants.

"We conduct traffic management through continued efforts with local stakeholders while maintaining driver awareness tools," said Broussard. "We are working at an elevation of 5 to 2. Any work with existing soils deals with working with ground water and maintaining drainage. Most known utilities are coordinated, although there will be coordination with pipelines that are to remain in place.

"It is tight area due to the utilization of the existing ROW," he added. "No additional ROW was acquired for this project. The goal is to resolve issues as quickly as possible at the lowest level of management on either side."

RDV System's Role

A goal on the $70 million interchange was to maintain specific design speeds on all connections and from the start, TxDOT was concerned about maintaining road safety standards.

While the non-compliance of some hazardous U.S. highways may originate in design, construction and/or maintenance deficiencies, there is a much deeper, more troubling issue at hand. AASHTO's "Policy on Geometric Design of Highways and Streets", a.k.a. the Green Book, provides two-dimensional schematic road safety methodologies that have not changed in over 70 years, despite the fact that 3D roadway modeling is now commonplace. The Green Book's guidelines are fundamental to roadway engineering. However, from a sight distance perspective, they focus primarily on vertical and horizontal curve values, with no practical method of evaluating many of the environmental and man-made hazards that impact driver safety, which resulted in RDV's Road Safety Audit 3D.

TxDOT approached RDV asking that it deploy its Road Safety Audit 3D to assist the PCI team in assessing the interchange design's sight distance and ensuring that it met AASHTO requirements.

Additional visualization characteristics were refined to reflect all environmental variables and RDV used the RSA 3D software to conduct comprehensive sight distance simulations of the turbine interchange's design.

It turned out that TxDOT's instincts were spot-on and its fears were corroborated — the design was deficient from a stopping sight distance perspective.

RDV coordinated with PCI to identify acceptable design alterations that complied with AASHTO design speed requirements. Fortunately, most of the problems could be resolved by restriping, i.e., shifting the positions of lanes to widen the shoulders on the insides of curves. Subsequent simulations passed the sight distance tests and provided confidence that the modified design truly met the accepted standards.

Analyzing the sight distance characteristics using manual tools and methods would have taken hundreds of hours to complete and might have required rebuilding the design from the ground up. Additionally, such analyses would inevitably rely on current practices which are not nearly as comprehensive as RDV's 3D approach.

RDV completed the safety assessment and helped update the design quickly and efficiently, keeping the project on schedule, avoiding costly downstream expenses, redesigns and post-construction adjustments. Above all, it ensured sight distance was compliant. CEG

Today's top stories